Glass Processing

Glass Processing

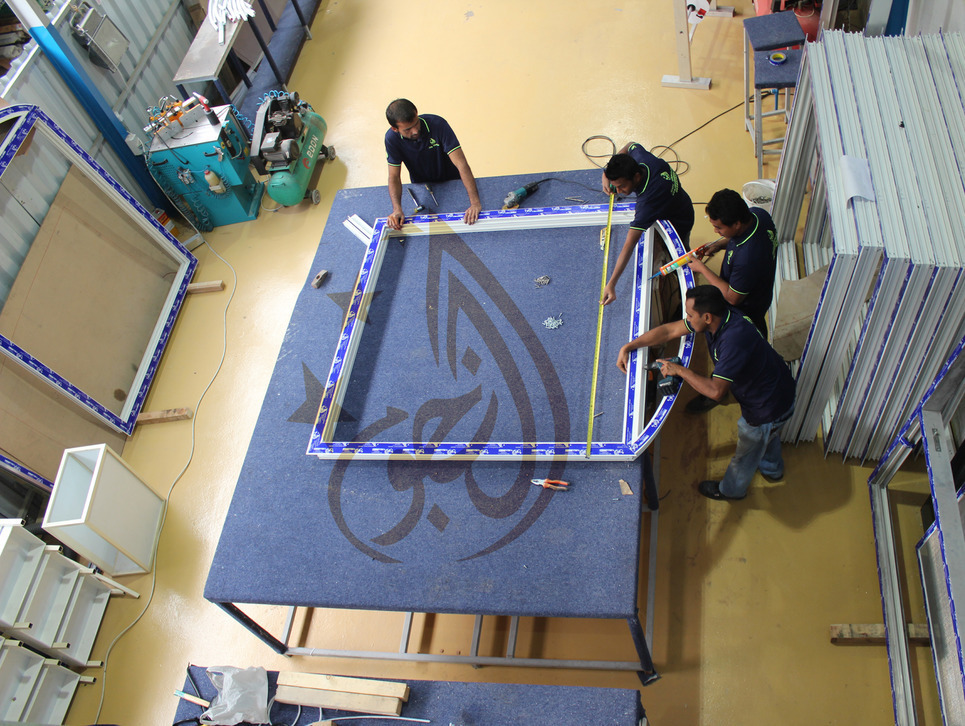

We employ a separate team of professional fabricators that are responsible for designing and installing glass into windows and frames. We have a glass processing plant in Sharjah that is capable of:

Cutting

With the use of our machine and tools available with a high level of accuracy. Based on the ranges of shapes we offer to cut glass according to the customer’s requirements.

Tempering

It is the process to create safety glass. It is the toughening of the thermal process, where the glass is heated to high temperatures before it cooled. this process is thermal toughening makes the glass four times stronger than ordinary glass.

Size: Flat Tempered Glass Max 2440*6000mm or 2850*5000mm

Min 300*300mm

Beveling

Beveling is a process where the surface of a piece of glass is cut at an angle, the thickness from the edge reduces towards the edge of the glass. It looks aesthetically pleasing by the mirror by deflecting or diffracting at different angles.

Size: Max 2000*3660mm or 2250*3210mm

Min 100*100mm.

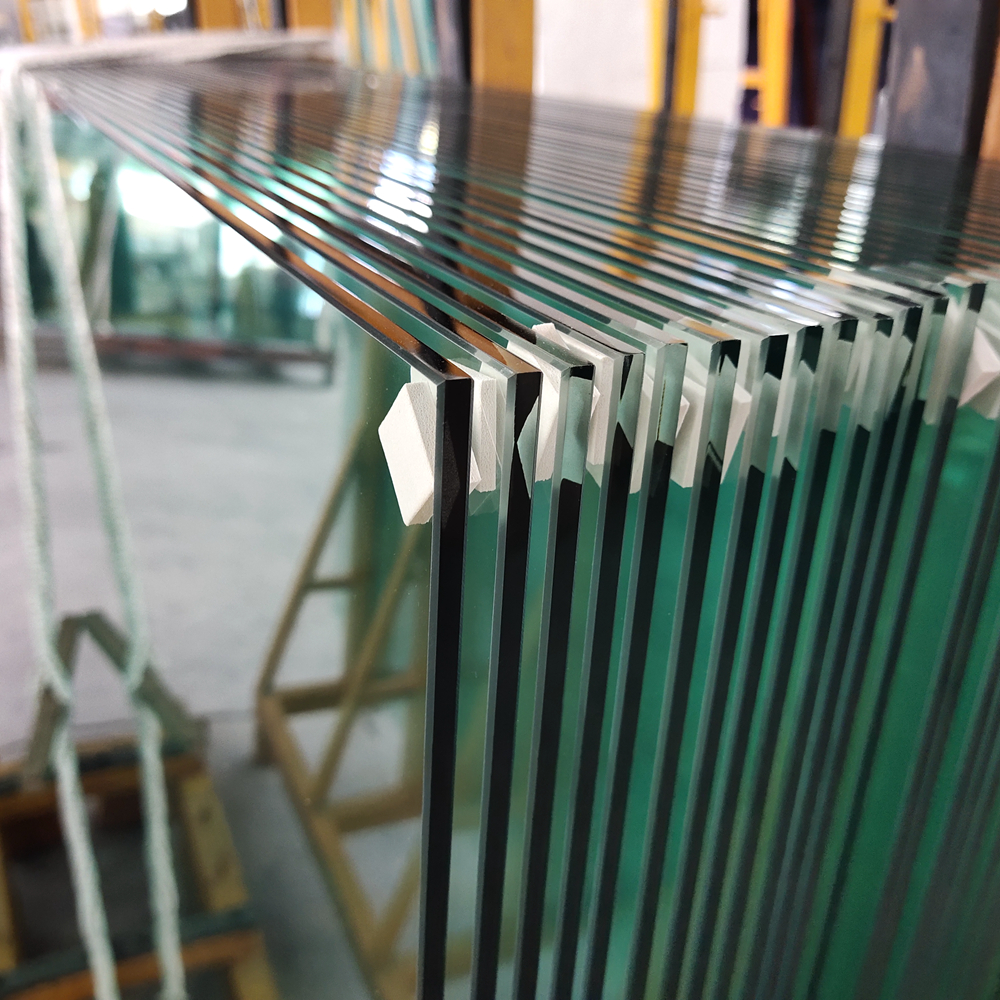

Lamination

Laminating involves sandwiching a layer of plastic (usually polyvinyl butyral or PVB) between two or more layers of glass. This process creates safety glass that holds together when shattered, making it suitable for applications where security and safety are paramount, such as windshields and glass balustrades.

Maximum working class

dimension 2440*6000mm

Polishing

This process provides a smooth even surface along with the edge of the glass. Polishing on the edges by grinding a thin layer displays a polished service.

All kinds of polishing, round polish, degree polish, 45 ̊mitering, round beveling.

Insulating

It is known as double or triple glazing. It contains two to three panels separated by a gas-filled space or vacuum to reduce heat transfer.

Frosted glass

This process creates a pitted surface on one side of the glass pane and has the effect of rendering the glass translucent by scattering the light which passes through, thus blurring images while still transmitting light. It has 10–20% opacity.

Application: windows, doors, shower doors,

furniture partition. Interior only.

Opaqueness: Light, medium, heavy.

Ceramic Glass

Glass-Ceramics are polycrystalline materials produced through controlled crystallization of base glass, producing a fine uniform dispersion of crystals throughout the bulk material. Crystallization is accomplished by subjecting suitable glasses to a carefully regulated heat treatment schedule, resulting in the nucleation and growth of crystal phases.

Size: Flat Max 2440*4500mm

Min 300*300

Double Glass

Double glazing is the glazing process in which a window is formed by two panes of Glass with a space between the panes. The space between the Glass is usually several millimeters thick. Air is trapped between the panes of Glass and forms a layer of insulation. Before the unit is sealed, a drying agent is added to ensure that no moisture is present inside the finished Glass unit.

Production Capacity

Cutting

One fully Automated cutting Machine with 1500 SQ M Per Day

Double Glazing

Total Double Glazing- 500 SQM Daily Output

Cutting

1000 SQ M per day (Capacity to increase to 3000sqm)